Technology

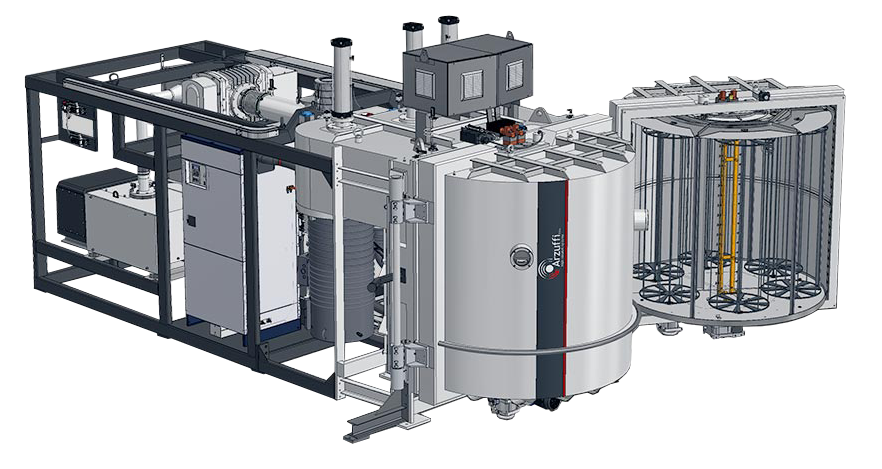

Lumotech operates multiple specialised assembly lines, each dedicated to the manufacturing and assembly of specific products. Here are some key technologies employed in Lumotech’s assembly lines:

Headlights:

Taillights:

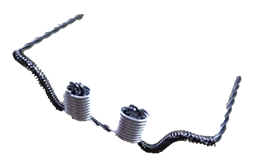

Given that some of our products include EMC components, all assembly areas adhere to strong Electrostatic Discharge (ESD) control measures in accordance with international standards such as ANSI-ESD-S20.20. Our employees are equipped with the necessary Personal Protective Equipment (PPE) to ensure compliance with ESD standards.