Technology

Direct Vacuum Metalising (DVM)

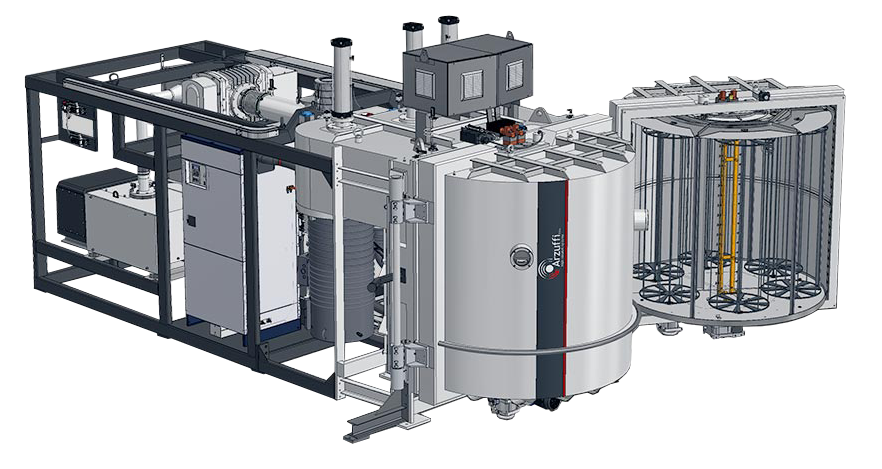

Direct Vacuum Metalizing (DVM) Is a post-moulding process employed For components requiring a highly reflective surface, whether For functional Or aesthetic purposes. The process involves placing the parts In custom jigs/fixtures And introducing them into the vacuum chamber Of the DVM machine.

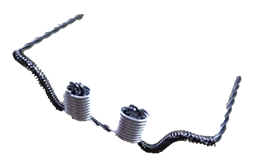

Initially, the parts undergo plasma treatment/glow charging to cleanse and enhance the surface tension, ensuring proper adhesion for subsequent coatings. Following this, aluminum is evaporated under high voltage applied to tungsten filaments positioned at the chamber's center, depositing aluminum onto the parts due to the line of sight. Subsequently, a layer of acrylic-based substance is applied to serve as a protective barrier against aluminum corrosion. All these steps occur under various vacuum levels.

Lumotech utilises a total of 5 machines for this process.