Technology

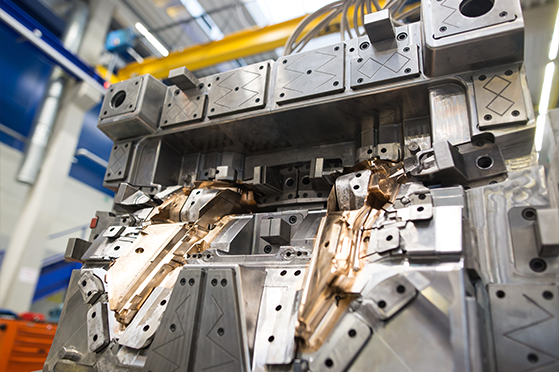

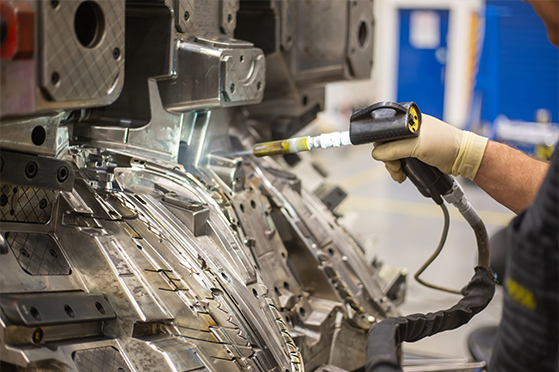

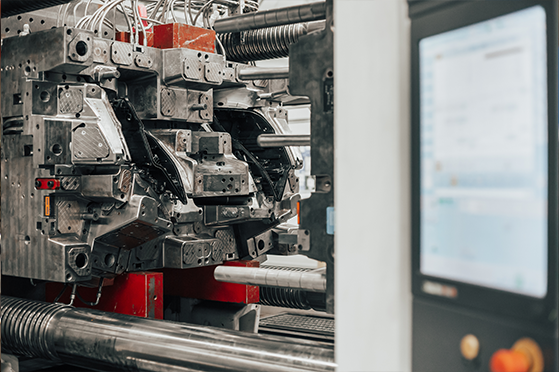

Lumotech boasts a well-equipped toolroom dedicated to the meticulous maintenance of all moulds. The services are efficiently monitored through an automated system that signals when moulds are nearing or have reached their service interval. Within Lumotech's toolroom, a dynamic dashboard provides real-time insights into tools requiring imminent or scheduled servicing, ensuring comprehensive team awareness and meticulous preparation.

The toolroom at Lumotech is proficient in executing engineering changes that align with the capabilities of their equipment. In instances where limitations are identified, the team is highly qualified to assess and may seek external assistance if necessary. When outsourcing work, Lumotech's engineers take a meticulous approach to manage changes or repairs with utmost care.

Key equipment available within Lumotech's toolroom includes a CNC Milling Machine, Alpha Laser Welding machine, EDM machine, Tool turning devices, Miniature Tig Welder, and various other engineering equipment and instruments used on a daily basis. This comprehensive array of tools empowers Lumotech to maintain precision and efficiency in their mold maintenance and engineering processes.